RIGHT TOOL FOR THE JOB

It’s your job to make sure the world keeps moving … and to do that, you need ice control equipment you can rely on. The all-new MARAUDER stainless steel hopper lineup is engineered to get the job done right. Choose the best material delivery system for your operation based on the de-icer you commonly use … either the all-new HELIXX™ shaftless auger for precise rock salt application or the pintle chain conveyor that’s perfect for thick, heavy de-icing materials. Whatever choice you make, you’ll get the delivery performance you demand.

HELIXX™ AUGER TECHNOLOGY

Patent-pending corkscrew material delivery system is optimized to operate in the target range for rock salt spreading best practices. The auger has multiple pitches to help promote smooth, even material flow from the hopper and prevents bridging. The shaftless technology reduces drag on the motor and reduces the overall load on the electrical system.

* * Auger Models Only (S150A, S220A, S300A, S400A, S500A)

PINTLE CHAIN CONVEYOR

The large conveyor delivers reliable, smooth, and consistent material flow for heavy, dense materials while reducing bridging.

* Chain Models Only (S150C, S220C, S300C, S400C, S500C)

HOPPER CONSTRUCTION

The hopper is made from corrosion-resistant stainless steel and constructed entirely of rivets and bolts, with no welding. This provides a cleaner stainless look and is easier to repair for long-life and protection against stress.

CONTROL

Enhanced dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions. Four standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency.

Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read. Its compact size compared to traditional controls fits easily into today’s modern truck cab designs.

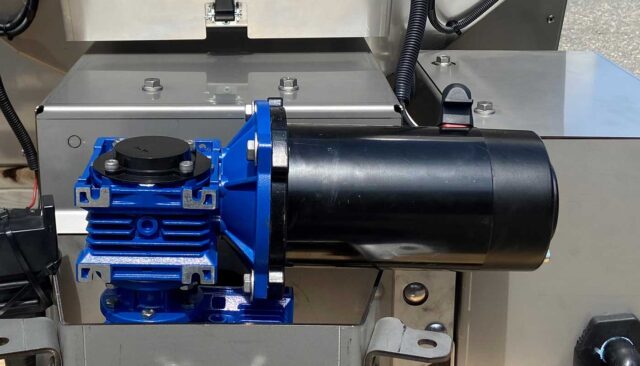

ELECTRIC MOTOR

The two high-torque 12-volt electric motors provide quiet, reliable and independent control over the conveyor and spinner mechanisms. The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion, while the conveyor motor is completely sealed from the elements.

SHUTTER DEFLECTOR

The easy-to-adjust circular shutter deflector allows directional spreading, providing optimal material control, while maintaining even coverage. For quick adjustments, simply move the convenient hand operated lever.

ACCESSORY INTEGRATION & KNOCK OUTS

Conveniently connect accessories directly into the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the truck. Hoppers feature knock-out holes for plug and play integration of certain accessories.

DUMP & WORK LIGHT SWITCHES

Operators can safely offload material or fill walk-behind spreaders by using the rear mounted dump switches. A third switch is also provided so that an accessory work light may be conveniently controlled from not only the cab but also the rear of the hopper.

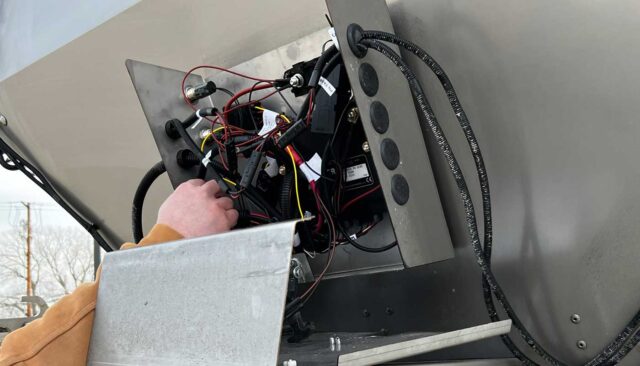

FLEET FLEX ELECTRICAL SYSTEM

WESTERN hopper spreaders are designed with FLEET FLEX technology for easy interchangeability between electric hopper spreaders without having to change the wiring or the controls. It provides easy operation, increased reliability, simple wiring and easy installation. Additionally, accessories automatically integrate into the control for easy plug and play.

For all orders exceeding a value of 100USD shipping is offered for free.

Returns will be accepted for up to 10 days of Customer’s receipt or tracking number on unworn items. You, as a Customer, are obliged to inform us via email before you return the item.

Otherwise, standard shipping charges apply. Check out our delivery Terms & Conditions for more details.